Dinger's Aviation Pages

Crikey!

Its development and production.

Don't Blame the Engines!

The Westland Whirlwind.

Its development and production.

Don't Blame the Engines!

The classic wartime colour photo of a "Crikey": Westland Whirlwind P7048.

In recent years, independent research by aviation historians Nialls Corduroy and Matt Bearman have shone new light on the British Westland Whirlwind cannon fighter of WW2; exploding some myths that have grown up about it. Yet that research seems to have gone unnoticed by most aviation enthusiasts. This brief webpage essay attempts to correct the narrative around the Whirlwind, but you are strongly advised to read Niall Corduroy's book and Matt Bearman's articles for a full understanding.

Origins.

In 1935 the British Air Ministry issued specification F37/35 calling for a fighter to be armed with four 20 mm cannon. The new fighter had to be able to serve as both a day and night fighter. It should be stressed that the original specification called for a single-engine type. It was only after Supermarine and Bristols suggested that two engines would be better able to lift the extra weight of the cannon that the Air Ministry revised the specification to include twin-engined designs. It is wrong to consider the Whirlwind as any sort of "escort fighter". Rather, like the Hurricane and Spitfire, it conformed to the wish to combine the roles of "interceptor" and "zone fighter" into one type, albeit with greater armament.

It was only a couple of years since the Air Ministry had adopted the rifle-calibre Browning machine gun for its next generation of fighters and it was only the previous year that prototypes of the Hurricane and Spitfire had been ordered. So it was a big leap to consider arming a fighter with no less than four cannon. European air forces were starting to use cannons, particularly the French who used single Hispano-Suiza HS404 cannons firing through the airscrew hub (the so-called "moteur-canon"). The Danish 20 and 23mm Madsen cannon was also getting coverage in the aviation press and the earlier Swiss Oerlikon 20mm cannon would end up being adopted by the Germans for their Bf109 and Bf110 fighters. The British chose the French HS404 as the basis of their development, which became the Hispano 20mm cannon. As originally developed this was fed by 60 round drum magazines, with a rate of fire of 700 rounds per minute this gave only some 5 seconds of firing time.

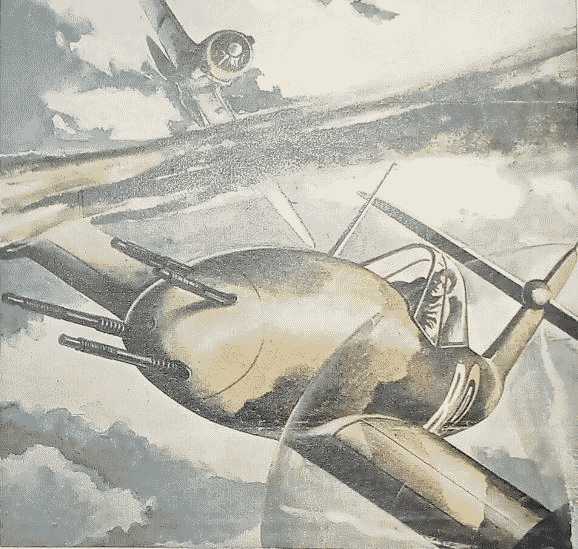

The Whirlwind's reason for existence: its four cannon armament housed in the nose. The installation gave RAF armourers a few problems; they would easily cut their hands on the exposed sharp metal surfaces when fitting magazines and the initial design of nose cone was difficult to get back on and line up the fastening holes, very frustrating if they were doing a quick turn-around to get it ready to "scramble" again. The nose cone was redesigned with a reduced number of fasteners and a central nut with locking pin on the tip. The cannon gave devastating fire-power, but with only 5 seconds of firing time, Whirlwind pilots had to be sure of their aim. Notice the intake for the engine radiators, built into the leading edge of the wing; the actual radiators did not take full advantage of the space available. Also, notice the fairing to contain the gun camera, another fairing could be fitted alongside it to catch the spent cannon cartridges on training missions (to recycle them).

Lots of British aviation firms put forward tenders for the specification. The single-engined contenders included cannon-armed derivatives of both the Spitfire and Hurricane, a Hercules radial-powered design from Bristols (the Type 153) and a Hercules (P88A) or larger Vulture powered design (P88B) from Boulton Paul. Vickers also tendered a design clearly based on the Spitfire, but using just two of Vicker's own 25 mm cannon. It should be noted that none of the twin-engined designs tendered used the latest, bigger engines of 1,000 hp or more. The Supermarine Type 313 used two of either the Rolls-Royce Goshawk (660 hp) or early Hispano12Y (880 hp) engines, the Bristol Type 153A used two Bristol Aquila engines (620 hp in AE-3S form), while the Westland P9 used the Rolls-Royce Kestrel engine (880 hp). This clearly shows that the current philosophy was to use two smaller engines that together gave greater power than any single-engine could then attain while being able to concentrate the armament in the nose of the aircraft. The Germans created the Focke-Wulf Fw 187,with two 670 hp Jumo 210 engines, to much the same formulae.

The Air Ministry ordered two prototypes of its favourite single-engined design, the Vulture powered version of the Boulton Paul P88, this looked like a larger, single-seat version of their later Defiant design. Of the twin-engined designs, the Air Ministry favoured the Supermarine Type 313, one of the last designs of the brilliant RJ Mitchell, and it was a single prototype of this that was initially ordered. When Supermarine was awarded a contract to build a new heavy bomber (the Type 316/317/318) it was obvious that the workload of the company was too much for them to handle, so the Type 313 fighter was cancelled. Instead, the Air Ministry choose the P9 design from Westland. This had some innovative features which the Air Ministry were keen to explore (teardrop canopy, slats, radiators in the wings, high-aspect-ratio wings, Fowler flaps). Crucially, Westlands would have both factory space and design staff to spare, with new workshops being erected and having finished their design work on the Lysander.

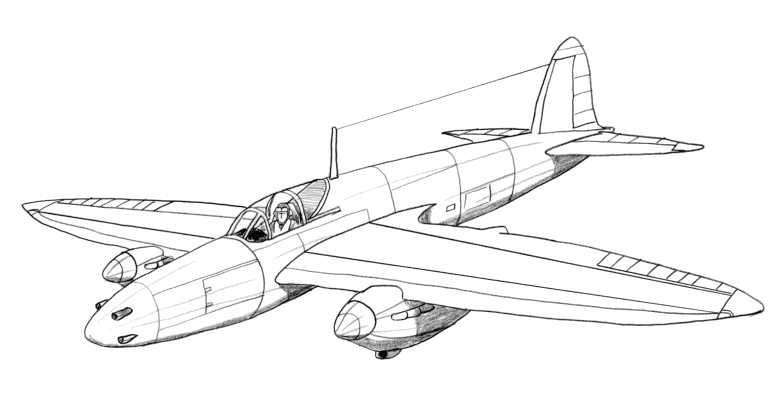

The Air Ministry's favourite twin-engined contender for F37/35; the elegant, long-nosed Supermarine Type 313 would have had to adopt the Rolls-Royce Peregrine when the steam-cooled Rolls-Royce Goshawk engine was dropped. Supermarine simply did not have the design staff and workshop resources to cope with the development of the 313 alongside the Spitfire and 316/7/8 bomber. In the end, only the Spitfire reached production.

The Air Ministry's favoured single-engined contender for F37/25; the big, robust-looking Boulton Paul P88B was to have been powered by a Rolls-Royce Vulture engine. Its designer, John Dudley North, anticipated many of the issues associated with 20mm cannons. He designed a rigid box in which the cannons were mounted on their side which could have avoided the issues of jamming caused by mountings flexing that plagued the Spitfire and Whirlwind.

By the time the Westland proposal was accepted, the latest development of the Rolls-Royce Kestrel had been renamed the Peregrine. The use of the Peregrine engine on the P9 must have also seemed a very risk-free choice. It was seen as essentially just the well-tried Rolls-Royce Kestrel engine (used on such diverse types as the Hawker Hart and Fairey Hendon bombers and the Hawker Fury interceptor) modified to use glycol cooling (which meant a smaller radiator and thus less drag) while running at a slightly higher speed (3,000 rpm compared to the 2,750 rpm of the Kestrel XXX) and having a more efficient supercharger. At this stage, the Air Ministry would have been very keen not to have another aircraft dependent on the Rolls-Royce Merlin. All the new fighters already on order for the RAF and also the Battle and Henley bombers were powered by the Merlin and delays in its production were beginning to cause sleepless nights for the Air Marshalls. In 1937 the Air Ministry was to go through a crisis of confidence in the Merlin when the early Mk I engines used on the Fairey Battle had constant failures. The Merlin came very close to being cancelled altogether, or at least its production being seriously curtailed.

If the Peregrine was seen by the Air Ministry as a simple upgrade to the Kestrel, then that fact was not communicated to Rolls-Royce. Battling with the unreliability of the early Merlins and with the Air Ministry clamouring for results, they decided to put the Peregrine on the "back burner" and concentrate on the Merlin. They reasoned they could then apply all the experience they learnt fixing the Merlin's problems to the Peregrine. Meanwhile, the Air Ministry had stopped ordering new Kestrels (the Kestrel XXX engines fitted to the Miles Master MK I trainers were reconditioned and updated engines stripped from the many RAF aircraft going out of service). So Rolls-Royce closed down the Kestrel production line to concentrate resources on the Merlin. This would have implications for starting full-scale Peregrine production. Like Rolls-Royce, we shall come back to the Peregrine later...

Westland, an Aircraft Company with Issues.

In the 1930s, the Westland Aircraft company was a hotbed of family and boardroom intrigue and argument. It had grown out of the West Country engineering company "Petters Limited", famous for the "Petter engine", derivatives of which are still being manufactured today. It had diversified into aviation in the Great War and did a fantastic job of manufacturing the designs of other companies (the Sopwith One-and-a-Half Strutter, de Havilland 4, 9, 9a, Vickers Vimy and Hawker Audax were all built by the company). Indeed, manufacturing aircraft designed by other companies was what it was good at. After the war, when the company designed its own aircraft, the results were pretty disappointing, with tiny production runs, except for the Westland Wapiti and Wallace that were developments of the wartime DH 9a. This family of aircraft were a particularly successful strand of developments for Westlands, spanning the period between the wars (large numbers of Wallaces were still in service when WW2 started) and also providing the basis for the aircraft that were the first to fly over Mount Everest in April 1933, something that made the Westland name well-known.

Westland produced all kinds of one-off, prototype or limited production run aircraft in the 1920s and early '30s, (some very strange indeed, try googling the Westland Dreadnought or Westland-Hill Pterodactyl for example). The Wessex trimotor airliner was a modest success but had no development potential. Their attempt at building a monoplane interceptor fighter, to specifications F20/27 and F29/29, was a failure; being outperformed by the biplane designs of other companies. Their bizarre biplane F7/30 fighter was another disappointment. Westland did make advances with a series of parasol monoplane designs, first the Westland Wizard, then the Witch and then the PV7. The PV7 came close to winning a major contract (read about that in my article on the Vickers Wellesley). It was this line of development that led to the Lysander.

Up until 1934, Westland's chief designer had been Arthur Davenport, a very competent engineer. It was Arthur who had guided Westland towards the high-wing monoplane layout at a time when other companies stuck to biplanes. In this, he was helped by very efficient production and manufacturing staff (after all, it was in the cost-effective manufacture of other peoples designs that Westland had built its reputation). It is one thing to design an aircraft with good performance, it takes another set of skills to break down that design it so that it can be quickly and economically manufactured and also serviced and repaired once in use.

In 1934, Sir Ernest Petter, effective owner of the company, had his 26-year-old son, WEW "Teddy" Petter, appointed to the board of the company and made him technical director and chief designer over the heads of Arthur Davenport and Professor GTR Hill (designer of the Pterodactyl projects). The young Petter had a somewhat abrasive nature, making enemies easily. He started off by sacking some of the longer-serving Westland employees. Over the following couple of years a lot of the senior staff at Westland, infuriated by Petter's behaviour, found themselves jobs elsewhere (with rearmament in full swing all the major aviation companies were hiring). Petter filled the vacant roles with people who often had no experience in the aviation industry (John Fearn, the new Works Superintendent in charge of production planning, came from a Midlands bicycle factory). The one person who did not leave was Arthur Davenport, he collaborated with Petter on the end of his PV7 project and worked with Petter to make substantial changes to the Lysander army co-operation design.

There is no getting away from the fact that the young Petter had a rare genius. He had studied aerodynamics at Cambridge University and would go on to be remembered as one of the great British aircraft designers. He seemed to have an innate, almost intuitive, understanding of the properties of air flowing around a body. Some of his designs featured innovations in advance of the contemporary knowledge of aerodynamics. His changes to the Lysander were the first hint at this talent, and the design quickly found favour with the Air Ministry, leading to a production order, (this was in stark contrast with his other project of the time, the CL20 autogyro, which was a failure).

The year after Petter was made technical director, the operations of the aircraft division was separated off from the rest of the company. Then a merger with the British Marine Aircraft company was proposed, a deal that Teddy Petter was strongly against and managed to get stopped by threatening to resign (this is a bit ironic, since British Marine Aircraft went on to become the Folland Aircraft Company, that Petter joined in 1950, designing the Gnat lightweight jet fighter and trainer for them). In 1935, Westland's finances were in such a state that the Air Ministry ran an investigation into the company's affairs, briefly threatening to withhold any further orders, and held off ordering the P9 for this very reason. In 1938, Sir Ernest Petter sold his majority shareholding to the John Brown Shipbuilding company. This move caused a rift between Teddy Petter and his father. The young Petter saw the loss of family control of the business as a huge betrayal.

Whatever Petter's feeling about the sale of the company, investment by John Brown (and further acquisition of shares by Associated Electrical Industries) did allow extra investment that would permit the production of the new P9 cannon-fighter alongside the Lysander (albeit the new capacity was on nothing like the scale achieved at the new "shadow-factories" being sponsored by the Government for rearmament at the time). When the Petter engine company was sold off, its production was moved to Loughborough. The empty factory, adjacent to Westland's Yeovil site, was acquired and proved crucial to expanded production. However, the loss of so many of Westland's "old-hands", because of Petter's lack of people-skills, led to serious problems in production planning, the very area Westland had built its reputation on. There was no one left who dared analyse and critique Petters design for easier production or maintenance. For example, when Harald Penrose the company's test pilot, strongly argued for an automatic trim system on the Lysander, Petter overruled him. This ended up being a serious deficiency in the Lysander, which cost a few pilots their lives (those who fly the remaining "warbird" Lysanders today have to be thoroughly briefed on the aircraft's peculiar flying qualities).

Westland had greatly impressed the Air Ministry with the swift production, under contract, of the Hawker Hector; all 178 examples of this army co-operation aircraft being completed in just 10 months in 1937. Westland also delivered the first Lysanders on time and budget. Subsequently, it seems things turned a little sour for the Lysander. On one Lysander Petter experimented with a new lightweight fabric covering on the wing to save weight. This was done without consulting or asking the permission of the Air Ministry and when the aircraft almost crashed, because the material tore away in flight, the Ministry began to have doubts about Petter. There were also issues with quality control and certain aspects of the design proved problematic, the problem of the trim system being the most serious. These sorts of things should have been sorted by a competent production design department. In 1939, Westland had to call in consultants from the American automobile industry to completely reorganise the company, after which it became a "model" to which the rest of Britain's aviation industry aspired. Westland's amazing wartime Spitfire and Seafire production record testify to the efficiency of the new system. However, the design of the P9 Whirlwind had taken place before these changes took effect and the issues of ease of production, repair and maintainability were already present in the design.

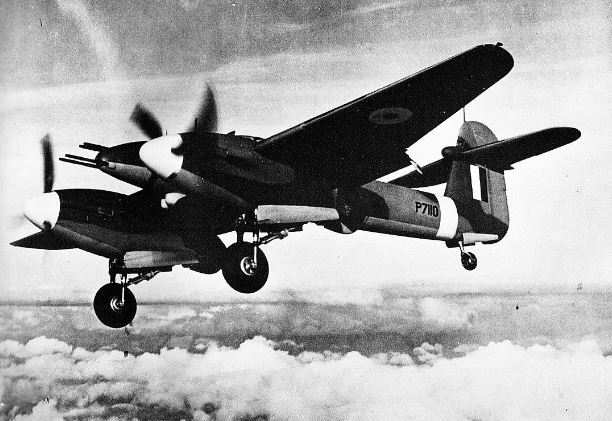

Production Whirlwind P7110 above the clouds. The term "heavy fighter" is often used nowadays to describe any WW2 fighter with two engines. This is a recent trend, started by the flight-sim and combat sim community to categorise aircraft. It is certainly not a term used during the war and is the antithesis of the Whirlwind concept, which was the smallest, lightest airframe that could be mated to the two Peregine engines. Its wingspan was only slightly wider than the Hurricane, yet it had less frontal area. Notice the pitot tube for measuring airspeed is mounted very high above the rudder; its location meant it gave inaccurate readings at low speed, not very helpful when landing! It was also difficult to put on and remove a safety cover over the pitot (to prevent insect ingress), requiring a high ladder.

This is the background against which the new P9 cannon-fighter was designed and two prototypes built. Petter went to great lengths to streamline the design (amazingly it has less frontal area than a Hawker Hurricane) and save weight (it was one of the first aircraft to make use of lightweight magnesium alloys). It had a teardrop canopy, with very little framing, to give excellent upward and rearward visibility. It had a fully retracting tailwheel at a time when most fighter designs still had fixed tailwheels. It had its engines enclosed in superbly streamlined nacelles, with radiators built into the wings for further streamlining. It had leading edge slats, those on the outer wing were automatic in operation, the slats inboard of the engine (above the radiator inlets) were linked to the operation of the flaps. As originally designed, the Whirlwind was to have had twin endplate rudders, but wind tunnel testing showed these would be blanked by the airflow around the large Fowler flaps Petter was keen to use. This prompted a new design with a single rudder with a high mounted tailplane (that high-mounted tailplane would cause issues later). Petter was confident his new fighter would have a top speed of 370 mph (595 kph) and a remarkable ceiling of 36,300 feet (11,064 metres) was predicted in the design brochure.

About the Peregrine.

Returning to the Peregrine engine. There was a concern that such relatively high-powered engines (880 horsepower each, 1,760 horsepower total) on such a light airframe would adversely affect the handling. The increased torque of engines during WW2 did indeed cause issues for aircraft designers and pilots. Westland had particular reason to be aware of the problem because it had adversely affected the performance of their earlier Pterodactyl V aircraft; its lack of traditional rudder area and a tandem undercarriage with wingtip stabilisers meant it had difficulty coping with the torque of its Rolls-Royce Goshawk engine during takeoff. There was also a theory, prevalent at the time, that the drag of a multi-engined aircraft could be decreased if the propellers could be made to rotate in opposite directions, producing a more symmetric airflow over the aircraft as a whole. For these reasons, Petter wanted to fit the prototype Whirlwind with propellers that rotated in opposite directions, each engine cancelling out the torque of the other. Amazingly, Rolls-Royce did this by building a Peregrine engine that was a complete mirror image! Effectively a completely new model of engine that Rolls-Royce called the Peregrine Mk II. The sheer craziness of this idea seems to have bypassed the Rolls-Royce engineers completely. It would have meant two different production lines to build Peregrines, and the RAF would have had to hold spares of both sorts of engines. A few years later, the very effective deHavilland Hornet twin-engined fighter had propellers that rotated in different directions, and they did indeed get rid of torque, giving the aircraft a fantastic performance and meaning no boot on the rudder was required as engine power was increased (the lack of torque meant that the Hornet could be safely used from aircraft carriers). The Hornet used Rolls-Royce Merlin engines, but the propeller was made to turn in the opposite direction on one of them by the simple addition of another pinion in the engine reduction gear. A very simple solution. The Whirlwind's big high-altitude successor, the Welkin, would also have the "handed" Merlin engines. Over in the USA the Lockheed P-38 "Lightning" fighter was also designed with two "handed" engines, its Allison V-1710 engine being designed to be easily modified for propeller rotation in either direction. The Air Ministry were not convinced by the argument for propellers rotating in opposite directions and stipulated that the second prototype should have props rotating in the same direction to allow a comparison to be made. Only if the first prototype showed a distinct advantage in handling or performance would the mirror image engine be ordered. The staff at the Air Ministry may well have remembered events during WW1 when Rolls-Royce produced two versions of its Eagle Mk I engine that rotated in opposite directions. These were used to power the Handley Page O/100 twin-engined bomber in an effort to reduce torque. It was later found that fitting engines that rotated in the same direction actually improved the flying characteristics of the O/100.

Prototype Whirlwind L6844, notice the propeller blades rotate in opposite directions.

Rolls-Royce slowly solved the issues of the Merlin engine and applied the results to the Peregrine. In one crucial region, they leapfrogged the current production Merlin (used in the Spitfire MkI and Hurricane Mk I). The glycol coolant used in the Merlin had one big drawback: it was flammable. The risk of fire was compounded by the fact that the coolant tank was normally housed in the nose of a fighter, and could therefore be easily hit by return-fire from the gunners on enemy bombers. There was also a looming issue that if the power of liquid-cooled aero engines was to be increased even further, then something even more efficient than glycol would be needed to dissipate the heat. The solution that Rolls-Royce came up with was to mix glycol with water, this made it non-flammable, and then put the resulting mixture under pressure so it was more effective at soaking up the heat. To take advantage of this new system, the Spitfire had to wait until the Merlin XII was available (first fitted to the Spitfire Mk II), while the Hurricane had it introduced in the Merlin XX fitted to the Hurricane Mk II, but the production Peregrine had the pressurised glycol/water system from the start (it is not clear if all the pre-production engines used on the prototype Whirlwinds had it). This should have meant that the cooling system should have been able to cope with any increase in power from future Peregrine developments (there were hopes the Peregrine could be boosted to 1,000 horsepower).

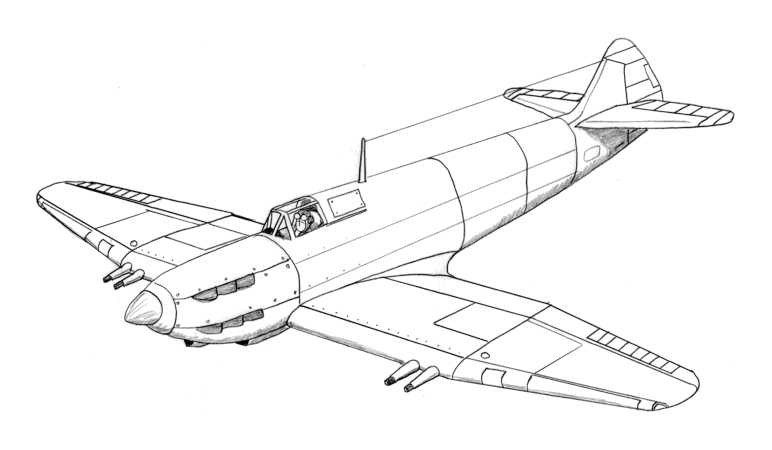

The Rolls-Royce Peregrine Mk I engine, it produced 880 horsepower and weighed 1,140 lb (517 Kg) compared to 1,030 horsepower at a weight of 1,375 lb (623 Kg) for the contemporary Merlin III engine. Some sources claim it could only run on 87 octane fuel, but the Whirlwind pilot's notes clearly state that they used 100 octane.

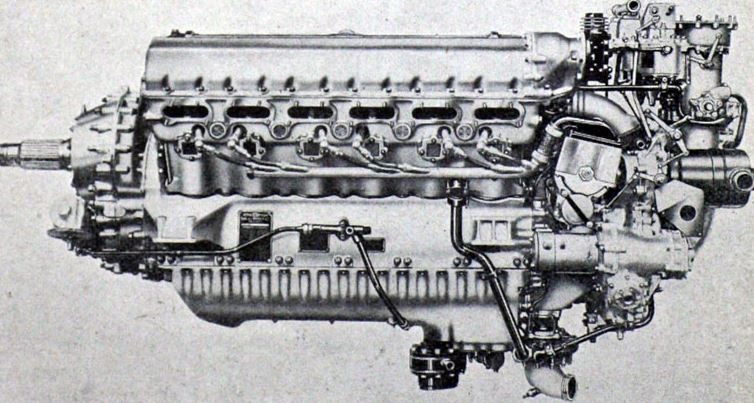

However, there were still a couple of problems with the cooling of the Peregrine engine on the Whirlwind that would become evident when it entered service, although neither of these problems was any fault of the engine itself but instead to do with its installation in the airframe. Petter had given the Whirlwind large intakes, in the leading edge of the wings, to feed the radiators which would be mounted inside the wings. When it came to sourcing the radiators for the Whirlwind, the only suitable ones that could be found were circular units, and three of these were arranged in a row, together with the oil cooler, inside each wing. Thus only part of the space available was used by the radiators. This was inefficient and caused an unnecessary drag on the air passing through. The other issue with the Whirlwind's cooling system was the way the rear radiator shutters opened and closed automatically with the operation of the landing flaps. Failing to raise or lower the flaps at the appropriate time during take-off or landing could cause the engine to either overheat or cool too quickly.The pilot's notes stress the importance of the correct operation of the flaps.

The inefficient circular radiators housed inside the wing of the Whirlwind. The smaller one on the left is the oil cooler.

YouTube video of the operation of the Whirlwind's Fowler flaps. Take particular note of the cooling shutter on top of the wing. This was linked to the operation of the flaps and could not be operated on its own. You'll see it is open to its maximum extent when the flap is in the 10 degrees down position; that is where you got the maximum cooling airflow through the radiators. If the engine started to overheat you had to put your flaps down to this position. When running up the engines the flaps had to be in that position and needed to be returned to that position if the engines were running hot. Since the radiators on the Whirlwind were only just about adequate to keep the engine cool a pilot had to be sure of the operation of the flaps. Petter meant this "all-in-one" solution to reduce the pilot's workload (most aircraft of this period had a separate control for cooling shutters or gills). Because of the Whirlwind's inefficient radiators, it ended up having the opposite effect, with a pilots having to continually operate the flaps in flight, with all the ramifications for speed and station-keeping that would bring. Also, note the way the rear of the engine nacelles are incorporated into the flap.

Prototypes and Testing.

The prototype Whirlwind (L6844) did not fly until 11th October 1938, well behind schedule because of the late delivery of the pre-production Peregrine engines. However, Westland had still been much more successful in building their prototype than Boulton Paul had with their P88B design. That was due to be powered by the new Rolls-Royce Vulture engine. Rolls-Royce kept changing the specification for the Vulture, altering its expected weight and power output. This made it impossible for John Dudley North, Boulton Paul's chief designer, to complete his design. The Vulture engine programme was well behind schedule and it was realised that if a prototype P88B was built there was unlikely to be an engine available to fit into it for some time. This led to the P88B being cancelled in February 1937. This is a shame since North had a particular interest and knowledge of weapon installation on aircraft and he seems to have anticipated many of the issues that would bedevil the installation of 20mm cannon in aircraft like the Spitfire and Whirlwind and built safeguards and solutions into the P88B design. Later (in September 1940) when cannon installations were proving unreliable on Spitfires and Whirlwinds, it was North who was put in charge of the team tasked with solving the issues (for details of the P88 design see "Boulton Paul 1917-1961 - Aircraft, Projects and Studies" by Les Whitehouse).

Initial trials of the Whirlwind prototype by Harald Penrose, showed up a multitude of problems, of which the engine cooling was the most persistent. With War looming the Air Ministry were under pressure to get the Whirlwind officially evaluated before the end of the year, So on the 30th December 1938, the prototype was rushed through a handling trial at Boscombe Down.* The brief testing turned up a list of only 12 fairly minor items to be rectified. This resulted in an "instruction to proceed" order being sent to Westland on the basis of an order for 200 Whirlwinds.

In the context of other aircraft contracts being awarded at the same time, it is very strange that the Air Ministry had waited until an evaluation flight of the Whirlwind had been flown. In the run-up to the expected war it was quite usual to order production of new designs "off the drawing-board". It does seem they were considering large-scale Whirlwind production, there is some evidence that at one stage the Air Ministry considered asking Supermarine to switch over to Whirlwind production once the initial, small, order for Spitfires was completed.¹ It was certainly true that the Air Ministry expected Whirlwinds to be produced at the new, huge shadow factory at Castle Bromwich, near Birmingham. One reason for the delay was the need to determine if production of the "mirror image" Peregrine was required, while Westland's test pilot, Harald Penrose, said it was because of a lack of faith in Teddy Petter by the Air Ministry.

Initial trials of the Whirlwind prototype by Harald Penrose, showed up a multitude of problems, of which the engine cooling was the most persistent. With War looming the Air Ministry were under pressure to get the Whirlwind officially evaluated before the end of the year, So on the 30th December 1938, the prototype was rushed through a handling trial at Boscombe Down.* The brief testing turned up a list of only 12 fairly minor items to be rectified. This resulted in an "instruction to proceed" order being sent to Westland on the basis of an order for 200 Whirlwinds.

In the context of other aircraft contracts being awarded at the same time, it is very strange that the Air Ministry had waited until an evaluation flight of the Whirlwind had been flown. In the run-up to the expected war it was quite usual to order production of new designs "off the drawing-board". It does seem they were considering large-scale Whirlwind production, there is some evidence that at one stage the Air Ministry considered asking Supermarine to switch over to Whirlwind production once the initial, small, order for Spitfires was completed.¹ It was certainly true that the Air Ministry expected Whirlwinds to be produced at the new, huge shadow factory at Castle Bromwich, near Birmingham. One reason for the delay was the need to determine if production of the "mirror image" Peregrine was required, while Westland's test pilot, Harald Penrose, said it was because of a lack of faith in Teddy Petter by the Air Ministry.

Back at Westland, test-flying of the prototype continued. It was apparently during this test-flying by Harald Penrose that the Whirlwind acquired its nickname of "Crikey!" because of its speed at low altitude. This testing revealed interference drag at the junction of the rudder and the high-mounted tailplane. This was fixed by the fitting of a wooden bullet fairing at the junction, an early example of an "anti-shock body", although the principle behind it was not fully understood until the 1950s. At first, only a small bullet was fitted to the prototypes and the first few production aircraft, this was later replaced by a much larger one.

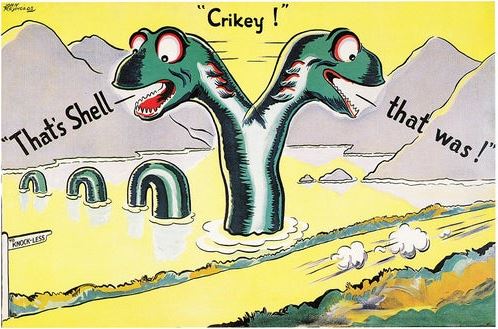

One of the numerous adverts for Shell petrol in the 1930s that featured the slogan "Crikey! -That's Shell, that was!", which became a catchphrase signifying anything that was exceptionally fast. The nickname "Crikey!" was given to the Whirlwind. The term crikey has largely fallen out of use in the UK but continues to be used in Australia (where it was a catchphrase of the zoologist and TV presenter Steve Irwin). You get an extra point if you understand the pun on the signpost.

Receipt of the "instruction to proceed" order, along with an advance of money from the Air Ministry, allowed work to start on setting up a proper production line. But the order for the Peregrine engines was delayed until after the second prototype (L6845) first flew in March 1939 and it could be compared with the first prototype.² Engine torque did make the Whirlwind pull to the left on take-off, but could be easily countered by the rudder and asymetric application of throttle, all the other handling qualities were much the same as the first prototype and its performance seemed to have actually improved. So the Air Ministry decided there was no need to have opposite "handed" engines and placed an order for just the one sort of engine from Rolls-Royce. Only then did they give a full production specification to Westland (in May 1939). In the meantime, the Air Ministry asked Westland to make changes to the design, primarily to the cockpit and radio layout, meant to standardise the location of controls across the RAF's new fighters and facilitate a switch from HF to longer-range VHF radios (the same changes were requested on the Spitfire and Hurricane). These changes had first been requested even before the first prototype had flown and the Air Ministry were astonished to find out that not only had their request not been addressed, it had not even been looked into. Petter reacted badly to any criticism of his design and took umbrage at the requested modifications, saying they would cause long delays to the aircraft getting into production. This caused some ill-feeling between Petter and the Air Ministry (particularly Wilfred Freeman who was in charge of development and procurement). In the end, a compromise was reached, it was decided that the first nine production aircraft would have no changes to the original design, from the 10th aircraft the changes to the cockpit layout would be introduced, and from the 25th aircraft the changes to the radio equipment would be incorporated; since the RAF planned to switch over to VHF control of its fighters this effectively made the first 25 aircraft a "pre-production" batch only fit for instructional use. That was the plan anyway, things didn't go according to plan, as we shall see...

The second prototype with propellers that rotated in the same direction. Its propellers were made by Rotol and had thinner blades than those made by deHavilland that were fitted to all other Whirlwinds.

Another modification had to be addressed in a much more urgent timescale. As originally designed, the engine exhaust of the Peregine engines was ducted through the fuel tank to exit near the rear of the upper wing; a consequence of Petter's pursuit of perfection for the streamlining of the engine nacelles. On a test flight by Harald Penrose, the ducting failed, burning through the control rod to the port aileron. Penrose was very lucky to land the aircraft safely; the implications if the bit of ducting that had failed had been inside the fuel tank do not bear thinking about. This forced the adoption of normal external exhausts on production aircraft.

Whirlwind of 137 Squadron in flight.

Into Production

In August 1939, only three months after the Whirlwind production specification had been officially issued, Rolls-Royce requested permission to drop the development of the Peregrine engine with a view to limiting its production run. It is important to note here that this request was only to stop further development, it was not a decision to stop any production (no production Peregrines had actually been built yet, only pre-production prototypes, the first production Peregrine was not handed over until February 1940). Initially, this had the opposite effect to what you might expect; the Air Ministry ordered even more Peregrines, on the assumption that they needed to ensure a full stock of these engines to meet future needs. They then ordered even more Whirlwinds from Westland, another 200, to take the planned production run up to 400.²

This action is misrepresented in most accounts of the Whirlwind's development. A request by Rolls-Royce to stop production of the Peregrine being blamed for the cutback and then early cancellation of the Whirlwind fighter. Instead, in his book "Whirlwind - Westland's Enigmatic Fighter" Niall Corduroy presents an entirely different version of events. The decision was taken in 1939 to greatly expand the size of the army that Britain would send to France in the event of war with Germany. That enlarged army would require more army co-operation aircraft to support it, and the only source of army co-operation aircraft was Westland with their Lysander. Westland would not have the space, manpower or resources to meet that need unless they stopped production of the Whirlwind. So the Air Ministry cancelled the Whirlwind on the 26th of October 1939, the month after war was declared and six months before the expected first flight of a production aircraft. There being no other aircraft that required the Peregrine engine, the Peregrine was also cancelled (the Miles Master trainer was due to switch to being powered by the Peregrine, but it could make do with the Bristol Mercury instead).

The Whirlwind was saved by a request from an unexpected quarter. The top-secret photo-reconnaissance flight at Heston needed a high-speed, high altitude aircraft for flights over Germany, and its request for the Whirlwind to be acquired for this role (stripped of armament and with additional fuel tanks) arrived just as the cancellation of the Whirlwind was being processed. The initial request was for just eight of such aircraft, and it was decided that construction of such a limited number would not stretch Westland too much. The order was then raised to eighteen, eight to be delivered without engines, to serve as spares. Then Westland made the case that a large number of component parts had already been made, enough to build a substantial part of over 100 airframes. Enquiries to Rolls-Royce then revealed that they too had built up a supply of parts ready for the start of Peregrine production. Some components of the Peregrine were common to the larger Vulture engine which was still going ahead at this stage. So it was decided to restart Whirlwind production with the intention to produce only 114 aircraft, 26 of them in photo-reconnaissance configuration and 88 fighters. The order to restart production was given on the 6th of December 1939. Documents in government files (Avia 46/119), uncovered by aviation historian Matthew Willis, show that the photo-reconnaissance Whirlwind was to have had the cannons deleted and the entire nose filled with an additional fuel tank to boost range. Even in April 1940, the wildly optimistic maximum speed of 373 mph (600 kph) was expected for the reconnaissance version, along with an operational ceiling of 32,000 feet (9,754 metres). There is a single reference to a "Special long range proposal with fixed undercarriage", which seems to be a version of Whirlwind undocumented in Westland files. The use of a fixed undercarriage would allow the fitting of extra fuel tanks at the rear of the engine nacelles, but there is also the intriguing possibility that it would enable the use of Merlin engines (the updraught carburettor of the Merlin would have obstructed a retracting undercarriage).

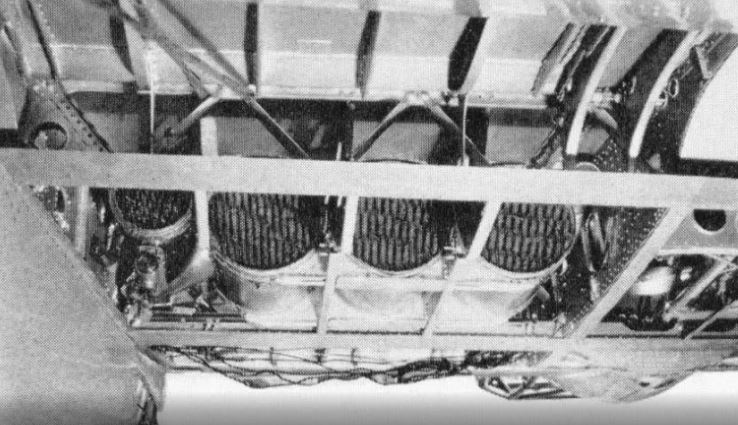

A table of the proposed production of British aircraft for 1940³ (compiled in December 1939) reveals that the first Whirlwind off the production line was expected in March 1940, peaking at 16 aircraft a month in September, with the last of the 114 to be delivered in January 1941. Even this modest expectation was to prove ambitious. The first production aircraft was not delivered until May 1940 with a dribble of deliveries (sometimes only 2 aircraft in a month) continuing until the last one was handed over in January 1942. The bottle-neck in production seems to have been the delivery of Peregrine engines, as soon as a pair of engines was available another Whirlwind would roll out the end of the production line. In the photograph of the interior of the Westland factory below, you can see two rows of Whirlwinds stretching off into the distance, all looking substantially complete, just missing their engines.

Whirlwind airframes awaiting their engines at the Westland factory at Yeovil.

So the Whirlwind gained a reprieve, the first production aircraft (P6966) flew on 22nd May 1940⁴, a dire time for Britain, German panzers had reached the Channel coast and the evacuation from Dunkirk would start the following week. In one sense Westland had done surprisingly well; the time taken from the issue of a contract to first delivery being considerably shorter than either the Hurricane or Spitfire (although the long delay in the Air Ministry issuing the contract would have allowed Westland to do much preparation work, albeit only by risking their own money on the chances of the contract being finalised). However, it was still much longer than Westland had promised the Air Ministry (September 1939 had been the date quoted for first delivery by Westland). In the meantime, the reason for that reprieve had evaporated. Testing of the prototypes showed a much lower ceiling, speed and range than anticipated, revealing the Whirlwind was not suitable for the high-altitude photo-reconnaissance role. In March 1940 its use in that role was cancelled, meaning the whole production batch was now to be delivered as fighters. You would have expected the Whirlwind programme to have been scrapped shortly after this; one suspects that if Wilfred Freeman had still been in charge of aircraft production it probably would have been. But in May 1940 the Ministry of Aircraft Production was formed with Lord Beaverbrook as its head (although Freeman was his chief advisor), and Beaverbrook asked Hugh Dowding, head of Fighter Command, if the Whirlwind should be scrapped. Dowding replied no, he thought that even a few Whirlwinds, with their heavy cannon armament, might have a pivotal role to play in destroying German landing-craft and tanks if an invasion of Britain was attempted. Dowding had been in charge of aircraft development at the Air Ministry when the specifications for the F7/35 cannon fighter had been drawn up and overseen the initial review of tenders, but he had left the role before the final decision to select the Whirlwind was made, and he seems to have had a very poor opinion of Westland. We can speculate he would have prefered a simpler, single-engined aircraft such as the Boulton Paul P88 instead. Once again, the Whirlwind was saved. Though, it was at the very bottom of Beaverbrook's production programme and would have been last on the list for material and component supply.

The Lysander proved to be a failure in its intended role in France. So suddenly, the additional orders for it were superfluous to requirements and a positive embarrassment to both the Air Ministry and Westland. Lysanders were also being produced in Canada and Westland had opened a whole new assembly facility at Doncaster to build Lysanders (this stopped after only 17 were bult and the Doncaster site eventually became a Wellington bomber repair centre). With the Battle of Britain in full swing it was fighters Britain needed, not Lysanders. Ironically, after the Battle of Britain was won, Dowding's successor as head of Fighter Command, Sholto Douglas, wrote to Westlands complaining about the lack of production of Whirlwinds while noting they were producing Lysanders "which nobody wants". He was seemingly unaware of the bottle-neck in Peregrine supply and that it was the Air Ministry that had prioritised Lysander production over that of the Whirlwind.

Don't Blame the Engines.

Returning to the Whirlwind's lack of performance at altitude, we now come to a subject that has almost defined the Whirlwind in the minds of aviation enthusiasts and pundits for generations: the performance of those Peregrine engines. Any number of books, magazine articles and internet forum postings damn the Peregrine engine with a lack of reliability and poor performance at altitude. Why should this be? How could a company like Rolls-Royce, who produced the superlative Merlin engine, have produced such a spectacular "dud" as the Peregrine, especially as it was just an upgrade of the earlier, very successful, Kestrel? Well, perhaps they didn't. There was indeed one major issue with the Peregrine you could blame on Rolls-Royce. Early in its service career there were a spate of fires in the engine. The source of the fires was quickly traced to the failure of a T-piece in the oil pipework of the engine. Replacement of the T-piece with one of stronger material, along with rearrangement of the pipework to cut down on vibration, solved the problem. Only two Whirlwinds had to perform emergency landings because of this issue (both being repaired and returned to service) and there was no loss of life or injury caused by the T-piece failure. A host of other "engine" problems were not due to the engine at all, but the way it was installed in the Whirlwind's airframe. Already mentioned is the unsatisfactory cooling system, with three circular radiators in each wing that could barely cope with keeping the Peregrine cool at full power, and a quirky interconnection of the flaps and the radiator openings that meant the engine could overheat (or cool too quickly) if operated in the wrong sequence. There were also issues with the lining of the fuel tanks becoming detached and clogging the fuel intake, causing an engine to fail. The other frustrating issue, that was never solved, was that the "exactor" hydraulic control system chosen by Petter, linking each of the throttle, mixture and propeller controls in the cockpit to the engines, could be erratic in operation with a considerable "lag". None of these issues was any fault of the Peregrine engine or Rolls-Royce.

Whirlwind P7110 in flight with undercarriage and flaps down. Notice that the rear of the engine nacelles are integral with the flaps and move downwards with them. Also notice this production Whirlwind does not have the mudguards on the wheels which were a feature of the prototypes. P7110 was one of the aircraft that suffered an engine fire because of the failure of a T-piece in the oil system.

What about the Peregrine's poor performance at altitude and complaints that it did not deliver the power expected? It is here that the research of Matt Bearman has revealed this not to be the fault of the Peregrine engine, but rather of the hydromatic constant-speed propellers, made by deHavilland. The propellers fitted to the second prototype (L6845) had been made by Rotol, and it was the second prototype that A&AEE ran their performance tests on, finding it had a decent performance at altitude, a ceiling of 31,000 ft (9,450m) and a top speed of some 354 mph. This was an excellent performance for a fighter of that period, but less than Petter had hoped for (a top speed of 370 mph and ability to get to at least 32,000 feet had been predicted, with a strong hope that 36,000 feet could be achieved). It was this disappointment that led to its use for photo-reconnaissance being aborted. However, the performance recorded by the second prototype would still have given the RAF a top-notch fighter if it had been replicated on production aircraft. Disappointingly, on production aircraft, fitted with the deHavilland propellers, performance fell off dramatically over 20,000 feet (6,100m) with a maximum height of 27,000 feet (8,200m); in attempting to reach this height the engine would usually show some sign of failure. The crucial difference between the Rotol and deHavilland props was the thickness of the blades, the deHavilland blades were thicker than the Rotol ones and were unusually thick for a fighter propeller of this period (they were of a profile designed by the American Hamilton company whose technology deHavilland licensed and subsequently improved). When a propeller blade rotates the air is pushed out of the way of the blade, the thicker the blade the faster the air has to move (the speed of rotation of the blade also comes into play here, the longer the blade the faster the tip of it will be moving). If either the thickness of the blade or the speed of its tip get to a critical point then the air will need to move at a supersonic speed to get out of the way of the blade. Effectively the propeller is breaking the sound barrier. The shockwaves produced will cause a sudden, massive increase in drag. Now some types of propeller can carry on through this barrier, although the increase in drag will affect the performance of the aircraft. But on a hydromatic constant-speed propeller like the deHavilland the constant speed mechanism tries to compensate for the slowdown caused by the increase in drag by altering the pitch of the blade. The effect is to create a limit to the top speed the aircraft can attain, it can never get beyond that speed no matter how much power is applied by the engine. Worse than that, the feedback from the propeller affects the running of the engine, making it run "rough" with fluctuating r.p.m. and boost pressure (exactly the symptoms seen on the Whirlwind). What has this to do with altitude performance? Well, the speed of sound decreases as you get higher in the atmosphere, due to the decrease in temperature and pressure. Thus a thick propeller may function okay at low altitude, but give a decreased performance at higher altitude. This is exactly what happened to the Whirlwind.⁵ For further details see the Whirlwind Fighter Project article at this link.

A few scientists and engineers understood this phenomenon at the time. A similar issue had threatened to scupper the Spitfire. When the Spitfire prototype first flew it did not reach the 350 mph top speed that had been expected of it, reaching only 335 mph. That was only 5 mph more than the prototype Hurricane was achieving. Supermarine feared that the Spitfire would be rejected for production if it did not show more of an advantage over the Hurricane. They ran through a series of initiatives to try to increase its top speed, all to no avail. Then the Airscrew Company, which made the Spitfire prototype's "Watts" fixed-pitch wooden propeller, said they suspected the airflow around the propeller was reaching supersonic speeds. They designed a new one with a thinner profile. With the new propeller fitted, the prototype Spitfire reached 349 mph in its trials at Martlesham Heath, ensuring the Spitfire was selected for service by the RAF. But the meeting of minds to associate supersonic airflow around the propeller with the Whirlwind's problems never took place (the fact that the second prototype Whirlwind had ever had different propellers seems to have been overlooked or ignored). Petter himself certainly seems to have blamed the Peregrine for the lack of performance of the Whirlwind.

Problems in Service.

Having laid to rest the myth of the "unreliable" Peregrine engine we can now address some of the very real problems of the Whirlwind.

1. The aircraft was not designed for easy maintenance. There was a lack of access panels to get at the various control runs, hydraulic and pneumatic pipes. This is a criticism often levelled at Petter's later designs (the EE Lightning was notorious for its access, with many an engineer's arm getting trapped inside the innards). The hydraulic system needed frequent "bleeding" to be kept servicable. The whole nosecone had to be removed to get access to the gun magazines and was initially very difficult to refit (this was partially addressed by a redesign). The coolant tank had to be removed to get access to some of the engine's spark plugs. Servicing the retracting tailwheel required the pilots seat, radio equipment and flare tubes to be removed to allow a mechanic to crawl down the inside of the long and tight fuselage. Sharp exposed metal edges inside the airframe would cut hands and fingers. One alarming official report said it was taking squadrons three to four days to change an engine and that the replacement of an outer mainplane had eaten up 200 hours of manpower. The notorious "team of six men with a crane, two hours to change a tyre" claim seems to have been exaggerated (official figures say one man in 32 minutes). The Whirlwind required a team of ten ground crew to maintain it, whereas a Spitfire or Hurricane required only three. Thus the servicing staff needed for a Whirlind squadron would have been enough to man over three Spitfire or Hurricane squadrons!

Cover of the "Air Ace Picture Library" Comic No 55 "Whirlwind in the Sky" from about 1960. It may well be this comic that is responsible for popularising the "team of men, two hours to change a tyre" trope so often quoted about the Whirlwind, since it features in the storyline. The tagline on the first frame of the comic goes... "It was a pilot's dream but a mechanic's nightmare...".

2. A lack of elevator control at low speed meant that high power needed to be maintained on the approach with a speed between 110 and 115 mph (for comparison the approach speed of a Spitfire Mk I was 85 mph). The pitot tube for the airspeed indicator was mounted high on the tail and could give inaccurate readings at lower speeds, which cannot have helped judging this. The high approach speed meant the Whirlwind's leading-edge slats were of negligible use. The Whirlwind's brakes were not very effective (a fact stressed in the official pilot's notes). All these factors meant the landing run was long; so the Whirlwind could not use the RAF's smaller airfields (although there were numerous cases of pilots doing so in an emergency). This was put forward as a reason for not using the Whirlwind as a night-fighter, long landing runs at night being seen as undesirable at the time (later in its service career it was sometimes used for night-intruder missions with mixed success).

3. The fuel systems for both engines were entirely separate. Each engine was fed by two tanks in the wing outboard of it. If one engine should stop for any reason the remaining fuel for that engine could not be diverted to feed the remaining engine. In a worst-case scenario, if an engine failed the decreased speed and increased flight-time meant the aircraft would run out of fuel before reaching base.

4. The cannons would often jam, or not fire at all. All of the aircraft using the Hispano cannon with a drum magazine in this period (Spitfire, Beaufighter, Hurricane) experienced issues, but on the Whirlwind it was especially irksome because the cannon armament was the chief reason for the type's existence. One of the solutions tried was to ease the pressure on the magazine's spring by not loading it to its full capacity (an old trick from the Lewis machine gun) but this reduced the miserable 5 seconds firing time even more.

5. As already mentioned, the "Exactor" controls for the engines and propellers were a constant cause of problems. They were a hydraulic system, meant to replace control wires. The hydraulic piping was somewhat fragile and prone to leaks. They had to be "primed" by cycling the control through its arc of operation a few times before use, obviously not something you want to have to do during a "scramble". If the pressure in the hydraulic pipes dropped then a considerable "lag" could develop between the pilot operating the control and anything happening. They could be reprimed in flight by operating the control through its full arc, but that's not going to help station-keeping in formation if you are going through the full range of throttle or propeller controls. Exactor controls were more suited to big four-engined bombers and transports than a fast fighter like the Whirlwind that needed more sensitive and quicker controls. However, even on big bombers like the Short Stirling, exactor controls were troublesome and late production Stirlings had them replaced with traditional cables and rods. The Exactor system dropped out of favour with British aircraft designers.

6. In early service, the Whirlwind experienced all sorts of airframe failures. Slats would become detached, wingtips were cracking and threatening to foul the ailerons, hydraulic pipes would fracture, the perspex of the cockpit canopies would crack and split open, carburettor intake ducts would fracture. Worst of all, tailwheels would collapse, often with the complete failure of the supporting bulkhead. The wingtip structures had to be reinforced and the cockpit canopies replaced with ones of a different design. It became necessary to replace the entire rear bulkhead, that the tailwheel was attached to, with one made of steel.

The redesigned nose of the Whirlwind did make it easier to fit back into place, but it did require an erk to edge out precariously to put the pin through the locking nut on the end.

That locking pin in close-up.

Things got so bad that the first squadron to form on the Whirlwind (263 Squadron) had to be moved down from Scotland to Exeter to be nearer the Westland factory so that issues could be fixed. Here we see the great advantage of the slow production of Whirlwinds. At this stage, only a handful had been delivered and the faults they exhibited could be addressed directly by Westland and the lessons learnt applied to the bulk of Whirlwind production still waiting on the delivery of Peregrine engines. The plans for the first few Whirlwinds to be "pre-production" types, restricted from combat, soon disappeared.

One further issue beset the Whirlwind a little later in its career. It was concerned the leading-edge slats outboard of the engine, which were automatic in operation. The inappropriate operation of the slats was suspected of causing the disintegration, in flight, of Whirlwind, P7008 on the 30th April 1941. An earlier failure of a slat (only 10 days before) had caused the crash of P6992. The loss of two pilots and two aircraft was followed, on the 9th of May, by the failure of another slat, although in this case, the pilot managed to land safely. Aerobatics in the Whirlwind were then banned while the effects of locking the slats shut permanently was investigated. It was found it had no effect on take-off and landing performance and made the Whirlwind more pleasant to fly! So it was ordered that all Whirlwinds should have their slats locked. This was just over halfway through the Whirlwind production run. From Whirlwind P7054 onwards, Whirlwinds were delivered from the factory with their slats already deactivated and locked shut (the last 44 aircraft of the production run).

The Whirlwind's high mounted tail design would probably have made it susceptible to the dangerous "deep stall" condition (sometimes called a "superstall"); this was not understood at the time. Harald Penrose encountered what seems to have been such a stall during testing and advised Petter that it should be investigated, but Petter refused permission. In the book "Whirlwind - The Westland Whirlwind fighter" by Victor Bingham there is an account by Iain Dunlop, a pilot of 263 Squadron, of what sounds just like a deep stall, brought about by use of the Fowler flaps. No losses of Whirlwinds can be directly attributed to deep stall but there are suspicions that some might have been lost to this cause.

In retrospect, remembering some of the problems encountered during testing, Harald Penrose concluded that the Whirlwind started to suffer from "Mach tuck" during dives. This again, was something not fully understood during the war.

Into Service

Whatever the agreement about how many aircraft were to be built with the initial cockpit layout, things turned out differently on the production line. The official pilot's notes detail which aircraft had the different layouts. The first 18 aircraft (up to and including P6983) had the flap and undercarriage controls on the starboard side of the cockpit. This was the "wrong" side to the standard RAF fighter cockpit layout and it meant the pilot had to swap hands on the control column when operating the flaps or undercarriage. The same aircraft only had provision for an HF radio which was served by an aerial sticking up from the cockpit canopy. Subsequent aircraft could have a VHF radio fitted and had the aerial offset to starboard in front of the windscreen (photos show the prototypes were also upgraded to this configuration). The same 18 aircraft had different locations for fuel, oxygen and electrical instrument gauges to the subsequent aircraft. An additional difference was that the first four aircraft (P6966 to P6969)⁶ had hydraulic, rather than pneumatic, operation of the Hispano cannon. These four aircraft had a single "fire" button on the control column that operated the cannon and gun camera at the same time. Subsequent aircraft had an additional button that just operated the gun camera independently (the cannon firing button still operated the gun camera when the cannons were fired). The presence of this extra button confused a few pilots and at least one Luftwaffe bomber escaped destruction because of it, leaving behind only cine-camera footage.

Whirlwind P6991 of 263 Squadron. It was the 26th production Whirlwind. It was delivered to 263 Squadron in February 1941. It served briefly with 137 Squadron in September 1941 before returning to 263 Squadron. It was written off following a forced landing (one engine failed on takeoff) in February 1943.

The Whirlwind seems to have been extraordinarily well-liked by the pilots who flew it in combat. Most accounts sing its praises and say it was easy to fly, once the quirks of its cooling system and the high-speed approach were mastered. The one consistent criticism is the limited amount of ammunition it carried. One dissenting voice stands out; Captain Eric "Winkle" Brown, arguably Britain's greatest test-pilot and the man who still holds the record for the most types of aircraft flown. He did not rate the Whirlwind very highly. He said its poor manoeuvrability and a lack of harmony of control made it a poor fighter.

A very scruffy Whirlwind of 263 Squadron, HE-V P6969. Notice the radio aerial sticking up from the cockpit canopy, this is indicative of the HF radio equipment fitted to the first 18 aircraft. The later Whirlwinds had an aerial in front of the cockpit for a VHF radio. Fighter Command delayed the switch-over to VHF radio and later operated the two systems alongside each other for a while. This was the aircraft lost with its pilot, Plt Off Kenneth Alfred George Graham, in the tragic incident that produced the first "victory" for the Whirlwind, an Arado Ar 196 floatplane. Details on the Aviation Safety website at <This Link>.

A handfull of Whirlwinds were tested by 25 Squadron in the Spring of 1940, but this squadron went on to be equipped with Beaufighters and never used the Whirlwind in combat. 263 Squadron operated the Whirlwind the longest, from July 1940 until January 1944. 137 Squadron was the other Whirlwind Squadron, flying the type from September 1941 until June 1943. It is not the purpose of this article to discuss the combat history of the Whirlwind. I will say that you should not necessarily trust early books on the subject or some of the online articles. Both Niall Corduroy and Robert Bowater have produced books that cover this in excellent detail (see sources list below). Corduroy's book is best on the technical aspects, and cross-referencing combats with actual Luftwaffe losses (with some surprising results). While Bowater's book is best on the personal side of squadron life, with some interesting mini-biographies.

A pilot climbs onto Whirlwind P7111 named "Bellows Uruguay No 2". The "Fellowship of the Bellows" was a fund-raising group started in South America by expat Britons and British sympathisers to raise money for the Royal Air Force. The name was an "in-joke", in that you use a set of bellows to raise a force of air (an "Air Force"). No 263 Squadron was supplied with seven aircraft paid for by the fellowship (the last seven Whirlwinds off the production line). Notice the cooling flap on the wing, raised to its fully open position. The metal ladder would be retracted up into the fuselage.

One thing to stress is that the Whirlwind was not used as a fighter-bomber straight away. It spent the first part of its operational life as an interceptor (not very successfully) and for patrols over convoys. Then it was used for bomber escort and strafing attacks on targets, within reach of its range, in France and Belgium; in this role, its limited supply of ammunition was a distinct disadvantage. Some of the Whirlwind pilots expressed suspicions that many of the aircraft targets they were attacking on German airfields were fake decoys. One aspect of the Whirlwind's career that is neglected is its use to attack small distilleries in France; these were using apples and sugar beet to produce ethanol for use as a fuel by the Germans. Whirlwinds only used their cannons for these attacks, rather than bombs, to try to avoid casualties to French civilians. The first "Whirlibomber" operation did not take place until 7th September 1942, some 8 months after the last production Whirlwind had been produced. After that, the Whirlwind came into its own with attacks on ships in the English Channel and on targets in France and Belgium. The bombs carried were usually two 250 lb (113 Kg), one under each wing. The Whirlwind was also capable of carrying larger 500 lb (227 Kg) bombs instead. The heavier bombs were rarely used because at the low levels the Whirlwinds delivered their attacks, there were fears that the blast from the larger bombs would damage the attacking aircraft. During its career as a fighter bomber (from September 1942 until November 1943) , Whirlwinds flew 1,427 combat sorties, 698 of those were against shipping targets. The final Whirlwind combat missions were flown on the 29th of November 1943.

Whirlwind P6997 was used to trial the carriage of bombs by the Aircraft and Armament Experimental Establishment (A&AEE) at Boscombe Down, where it was photographed extensively. It seems to have retained the HF radio installation, with associated wire aerial strung from the mast in front of the cockpit, long after the Whirlwinds with combat squadrons had switched to VHF radios.

Some web articles suggest that Whirlwinds modified to carry bombs were redesignated "Whirlwind Mk II". There seems to be no evidence for this. The pilot's notes for the Whirlwind Mk I were modified with a simple two-page addendum on the carriage of bombs with no change to the designation. It was not thought necessary to change the mark number of other types of aircraft when they were modified to carry bombs (Spitfire, Hurricane and Beaufighter for example), so its hard to see why it might have been done for the Whirlwind.

A fanciful cover painting from the Italian aviation journal L'aquilone of July 1942. It features a Whirlwind in combat with a Macchi MC 200. The Whirlwind was destined to only see service on the Channel coast, although the specification to which it was built stipulated it should be fit for service anywhere in the world.

The existence of the Whirlwind was kept secret from the British public until March 1942 when it was announced to much fanfare. This was two months after the delivery of the last Whirlwind. There had been mention of "a secret twin-engined British aircraft" in the media before, but no specifics or photographs.

The "Whirlwind MK II", and armament upgrades.

At a meeting in February 1940, some three months before the first production Whirlwind flew, Petter outlined some improvements designed to enhance some of its strengths and address some of its shortcomings. It seems Petter hoped for a reversal of the earlier decision to restrict production to just 114 aircraft, and so he was proposing a "Whirlwind Mk II". Despite Rolls-Royce saying they wanted to stop Peregrine development, it seems they had gone ahead and investigated boosting the engine. They did indeed run such tests on the first production Whirlwind (P6966) apparently with success. This had the potential to increase the power of the Peregrine to that of the mark of Merlin in the current version of the Spitfire, albeit for short periods. There was an obvious advantage in performance to using two such engines in the Whirlwind. Petter proposed the developed engines mated to a new design of Rotol propeller with increased range of pitch (Petter would have had no clue at this stage that deHavilland propellers would have such a disastrous effect on the performance of his fighter). He also advocated replacing his system of circular radiators with a new type of radiator that could be made in a "block" to fill the full width of the radiator enclosure in the wings. This promised to cure the problem of engine overheating. The design of the Whirlwind would be slightly altered to address some issues of turbulence discovered by wind-tunnel testing of the second prototype at the Royal Aircraft Establishment (RAE). With these improvements Petter expected the Whirlwind to exceed 400 mph (644 kph), remembering he still expected the original Whirlwind to reach 370 mph (595 kph). To address the serious issue of the small amount of ammunition per gun carried, and in light of the emerging problem of stoppages with the drum magazines, it was proposed that a new design of ammunition feed be looked at. The first one considered was that being developed by Bristol for the Beaufighter, but this was dropped in favour of the "Hydran" magazine system. This unusual pneumatic worm-drive driven device would hold 121 rounds for each gun, doubling firing time to some 10 seconds, still 8 seconds less than a machine gun armed Spitfire of the time. The Hydran system allowed the four cannon to be arranged in a horizontal row lower in the nose of the Whirlwind, which gave room for an additional small fuel tank in the nose. The changes to the fuel system would also address the separate fuel supply to each engine, introducing the ability to pool the supplies from all tanks.

Hopes of a new source of Peregrine production were briefly raised when the Royal Navy asked if it could be adapted to power motor torpedo-boats and be built by the Packard company in the USA (a hoped-for supply of Italian aero-engines to power such boats had failed when Italy declared war in June 1940). In the end, Packard's own design of marine engine was used instead, although they did go on to produce the Merlin in great numbers. Meanwhile, the Air Ministry and Ministry of Aircraft Production remained sceptical about the Peregine's development, although it seems that Rolls-Royce was allowed to go on investigating the potential. But the Air Ministry was enthusiastic about the armament changes that Petter proposed. They saw it as an upgrade that could be easily done to the existing order for 114 Whirlwinds, greatly enhancing their effectiveness and with the new nose being easily retrofitted to Whirlwinds already produced with the old drum magazines. In July 1940, the first prototype (L6844) was fitted with a new nose. At first, it only held a single 20mm cannon with the Hydran magazine (a photo of this installation appears in a lot of articles about the Whirlwind, wrongly labelled as being a 37 mm or 40mm cannon). Tests did not go well; nevertheless, the aircraft was upgraded to the full set of four cannon with Hydran feeds for further tests. These went even worse, the pneumatic system on the Whirlwind simply could not cope with the needs of the Hydran feed system, the system could not cope with negative-g manoeuvres, the magazines proved to be fragile while being too heavy to be man-handled into position for reloading. The Hydran system was dropped and one based on the belt-fed "Châtellerault" system was fitted instead. This was found to be satisfactory (it was the system adopted on the later Beaufighters, Spitfires, Hurricanes and later British fighters) but it was never used on production Whirlwinds, which ended up doomed to stay with the low-capacity drum magazines for its service life.

The first prototype L6844, still with props that rotated in opposite directions, but with a longer nose that accommodated the four cannons in one horizontal row that allowed the carriage of double the amount of ammunition in the "Hydran" magazine system, and later in the belt-fed "Châtellerault" system. This would have allowed a firing time of 10 seconds.

Petter did come back with a new, improved Mk II Whirlwind, This would have had the cannon with Châtellerault belt feed supplemented with three Browning .303" machine guns, with 400 rounds per gun, mounted above them in a slightly extended nose that incorporated a small fuel tank. In the rear of the fuselage was to be a second fuel tank to increase quoted endurance by some 40 minutes and increasing Westland's quoted range for the Whirlwind from 720 miles (radius of action 360 miles) of the Mk I to 900 miles (radius of action 450 miles). These figures are sometimes used to put the case that the Whirlwind could have been used as an escort fighter, getting most of the way to Berlin! However, Fighter Command considered the safe radius of action of the Whirlwind Mk I to be only 120 miles. Only a third of the distance suggested for the Mk I in the figures provided by Westland. What also sometimes confuses discussions about the range of the Whirlwind is the claim, in some wartime and early post-war publications, that they escorted Blenheim bombers all the way to Cologne (on the 12th of August 1941 to attack power stations). In fact, the Whirlwinds had to turn back near Antwerp, some 100 miles short of the target, having no further range than the Spitfires also escorting the raid.

In the Spring of 1941, it was suggested that a single 40mm be mounted in the nose of Whirlwind to serve in the anti-tank role (with Russia not yet invaded an invasion of Britain was still expected). It was envisioned that the whole of the Whirlwind production run could be converted. The idea was dropped, but was taken up again at the end of the year and seriously considered, with Nash & Thompson subcontracted to carry out the work. It was envisioned that a single Vickers 40mm "S" gun would be mounted in the nose with two Browning machine guns for sighting purposes. The idea was dropped in January 1942 (later that year, pairs of Vickers S guns were used by Hawker Hurricanes in the Western Desert with great success). There would appear to have never been an actual Whirlwind modified to carry such a weapon (or the American 37 mm cannon as used on the Airacobra, as is sometimes claimed) although sometimes photos of the single 20mm Hydra cannon installation are labelled as such.

No, it is not a 37 or 40 mm cannon, as is stated in old books, articles and web-pages about the Whirlwind. It is the first experimental mounting of a single 20 mm Hispano cannon with a Hydran magazine system. You can see the cannon is too small to be any larger calibre and is offset slightly to port. Compare it to the four-cannon layout in the photo above and you'll see that the other 3 cannons were then aligned horizontally around it, two to starboard and one to port..

While looking at different armament, it is as well to mention that, early in the Whirlwinds development, there was a fear that the Hispano 20mm cannon would either not be produced in sufficient quantity, or be shown to have some unexpected defect in service. To cover such an eventuality, the Air Ministry requested Westland to design an alternate nose containing 12 machine guns. The design produced by Westland was rejected by the Air Ministry, and Martin-Baker designed an improved version which was judged to be much superior, but there is no evidence it was ever fitted to a Whirlwind (Martin-Baker had earlier designed a 12 machine gun nose for its own private-venture twin-engined fighter, so it had a bit of a head start). The Martin-Baker design provided 500 rounds for each gun, which would have given five times the duration of fire, some 26 seconds.

Returning to the issues experienced with the Peregrine engines, it should not be thought that Rolls-Royce "washed their hands" of its problems; on the contrary, they asked for the worst-performing Whirlwind to be sent to their airfield at Hucknall for a thorough investigation. The RAF sent the second production machine, P6967, on 23rd September 1940. During its stay, it was reportedly fitted with the block-type radiators that Petter had hoped to fit to his "Whirlwind Mk II". These were in some sort of external fitting, but it is not clear if this was in the form of "beard" type radiators (like on the Hawker Typhoon) or under the wings (like on the Spitfire) no photograph of the installation has come to light (there are photos of it with air-scoops above the engine for added ram-effect for the downdraught carburettors). Even though the new radiator installation was external, the top speed of the Whirlwind at low-level was improved by some 12 mph (19 kph). With these improvements, the aircraft was passed on to the Royal Aircraft Establishment at the end of 1941. The new system was not adopted and P6967 was returned to the normal configuration in March 1942, seeing service with 137 Squadron before being used as an instructional airframe at RAF Hednesford from April 1943.

The Merlin Whirlwind and the Welkin.

With the Peregrine engine consigned to only a small production run the only way the Whirlwind could be resurrected was if some other engine could be used instead. There was some talk of using Allison engines from America, but the obvious choice would have been the Peregrine's big-brother, the Merlin. Long pooh-poohed on internet forums as being unfeasible, the research of Niall Corduroy has found that such a scheme was indeed considered and design studies got to quite an advanced stage. There was too little clearance between the fuselage and the engines to use any of the standard Merlin propellers, so shorter, four-bladed ones would have to be used instead (similar to the ones used on the later deHavilland Hornet). The other problem would have been the location of the Merlin's updraught carburettor, which would have protruded into the space used by the undercarriage (the Peregrin had a downdraught carburettor that sat above the undercarriage enclosure). This would have meant the Merlins would have to be repositioned further forward with a corresponding redistribution of weight in the rest of the airframe (the later Merlin 130 series, used on the deHavilland Hornet fighter, was redesigned to have a downdraught carburettor, but this did not become available until 1945). In any event, Westland seemed confident they could produce a Merlin-powered Whirlwind. In a letter to Sholto Douglas, in January 1941, they said their new design, with Merlin XX engines, would have a top speed of 410mph (660 kph), a ceiling of 37,000 feet (11278 metres), a range of 800 miles (1287 km) and carry an armament of four 20mm cannon with 120 rounds per gun and an additional two machine-guns. At the time, it was expected that the Luftwaffe would renew their attack in the Spring, and every Merlin XX engine was desperately needed to build Hurricane Mk IIs to re-equip the squadrons flying the earlier Hurricane Mk I, so this plan would have been a non-starter.